Quality Manager in the automotive industry (lines, valves and thermostats)

Time period:

2015/04 – 2016/07

Quality Manager in the automotive industry

Industry:

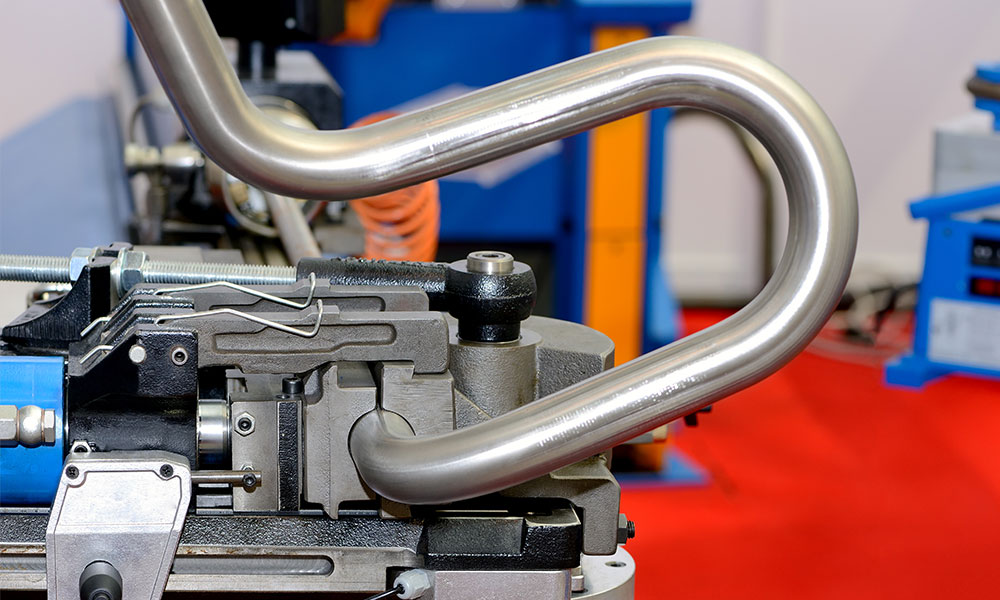

- Metal industry

- Automotive industry (pipes, valves and thermostats)

Turnover:

- 10.53 million €

Employees:

- 30.000

Country:

- Germany

Task:

- Complaint processing using 8D reports

- Experience with pipes, thermostats or valves

Measures:

- Practical intensive training of the individual MA during troubleshooting

- Scientific investigation and documentation of a repeat error

Successes:

- Project lead on exit from Qhelp3, with success on Qhelp1.

- Complaint support for repeat complaints and new issues

- Supplier and customer support (German and English-speaking regions)

- Error management (monitoring of 8D meetings, documentation)

- Constant cooperation with Daimler Trucks and Passenger cars

- Preparation of a production relocation (from Germany to Hungary) for VW (Skoda & Audi), Daimler, BMW, Ford, Continental

Special challenge:

- Production was relocated, employees no longer motivated

- In the initial phase, occasional aversion to outsiders noticeable

- Convince project managers that a scientific examination of a defect is financially worthwhile and can yield far-reaching optimization results