Interim Quality Manager in the metal industry (door closing systems)

Time period:

2022/01 – 2022/05

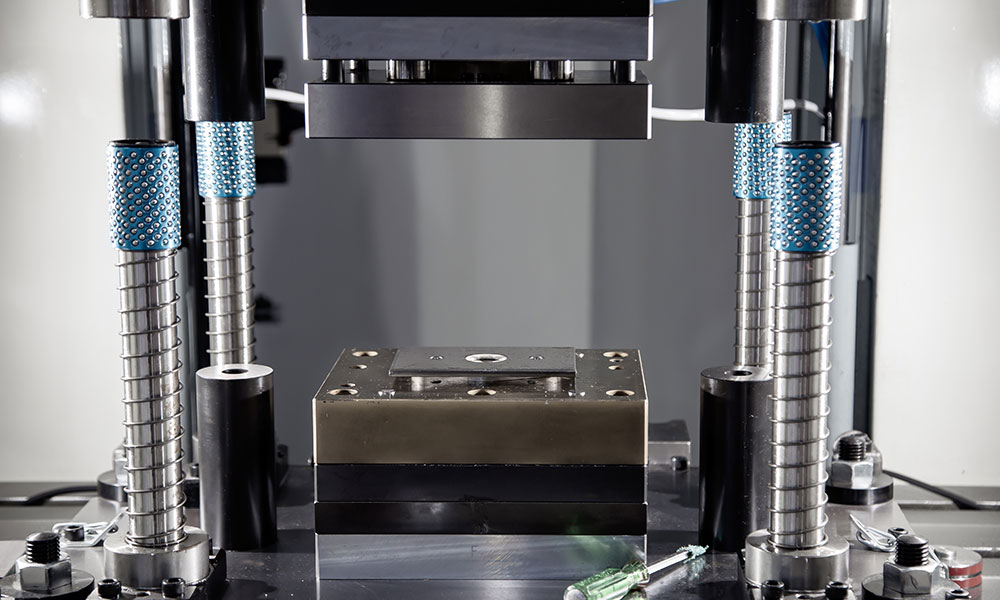

Interim Quality Manager in the metal industry

Area of responsibility: 25 employees

Industry:

- Metal industry

- Door closing systems

Turnover:

- 95 million €

Employees:

- approx. 650

Situation in the company:

- The Quality Manager in permanent employment was terminated in a flash, he was immediately released from his duties

- Handover took place by the management

Country:

- Germany

Task:

- Responsibility for quality management in the plant (production, customers, suppliers, projects)

- Leadership and further development of subordinate employees

- Responsibility for the continuous improvement of the QM system, methods and strategic orientation

- Problem analyses and coordination of the error correction process in close cooperation with internal departments, customers and suppliers

- Ensuring the quality of mechanical, electronic and electromechanical components and systems as well as integrated digital components / systems

- Development of quality concepts for new projects and series

- Development of a sustainable quality strategy / recommendation for action on the basis of a weak point analysis with the focus on organization, processes, products and employees.

Measures:

- Sensitization and training of employees through background information and lived error culture

- Activities within the scope of personnel responsibility incl. job interviews

- Preparation of a 3-year strategy for personnel (training, transfer, increase, exchange, change), organization (insertion of new structures and responsibilities) and technology (increase of machinery) incl. key figures

- Regular reporting (reviews) to the management board

- Cross-plant topics (procurement guideline, 8D report, special releases, advanced product quality planning (APQP), presentations, workshops) in coordination with the other Quality Managers

- Invitation of the sister plant for the purpose of joint reduction of defective deliveries and components

Successes:

- Reduction of complaints by about 20%

- Increased understanding of error culture and transparency created

- Reduction of special releases

- Synergy effects in other departments and between plants

Special challenge:

- Build trust with employees, guide, challenge and encourage them

- Preparation of various reports (documents deleted by ex-employee)

- Involvement of the team in the preparation of reports and management reports. (In the past, team was not involved).

- Communication and understanding between plants was strained